Part I Preface

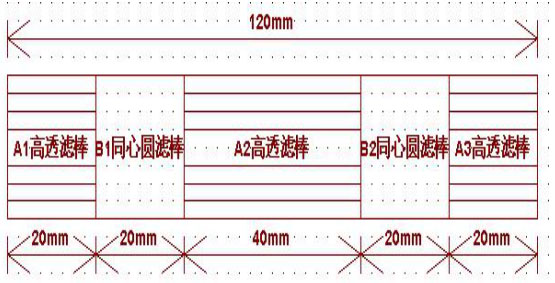

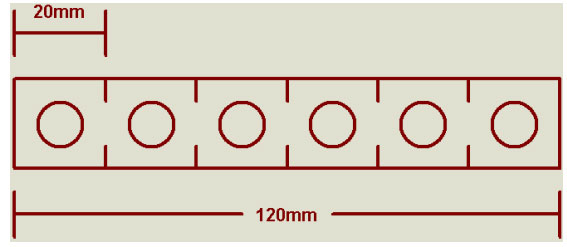

At present, cigarette filter has been developed from single function to multi-functional direction, in the high-grade cigarette, started to use a large number of composite filter stick, set the development of harm reduction reduction composite filter coke, aroma filling function of incense and outstanding product differentiation as one of the best, has become one of the key research of Chinese cigarette. The composite filter rod is usually divided into two to three different filter rods, which are cut and spliced by a special composite filter rod forming machine. The requirements of a composite filter rod production process are shown in the following figure:

1. Among them, the A1 section, A2 segment and A3 segment are made of ordinary high permeable filter rods, and the B1 and B2 segments are concentric circle filter rods. The whole composite filter rod has a length of 120mm, except for the length of A2 section 40mm, and the remaining sections are 20mm long.In the process of production, it is easy to have the following defects that seriously affect the quality of products:

1 Splice gap;A segment filter bar and B segment filter bar between the stitching is not tight, resulting in cracks .

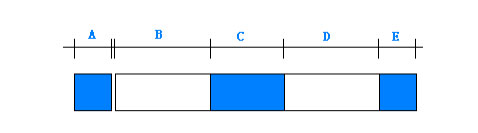

As shown in the following figure: when the adjacent two segments, such as A+B, do not equal the total length of the target, and when the error is greater than the set value, it is determined that there is a gap in the composite filter rod, and the output rejection signal is output.

Rejection condition:

(A+B)-(a+b) ≥︳0. 5??/FONT>mm

A+B is equal to the theoretical length of the two segments of A and B, and a+b equals the measured length of the two segments of A and B.

2. Filter stick malposition ;即Should be placed in the A section filter stick position, wrong into the B section filter stick .

3. Phase shift ;The length of A section filter rod and B section filter rod do not meet the requirement of process quality.

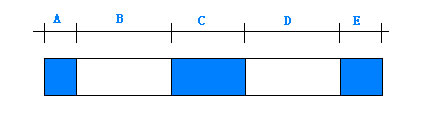

As shown in the following figure: when the length of the A segment is not equal to the length of the E segment, and when the error is greater than the set value, it is determined that the composite filter bar is a phase deviation and outputs a rejection signal.

Rejection condition:

a-e≥︳1.0??/FONT>mm??/FONT>

A is A section theoretical length, E is E segment theoretical length, a is A segment length, and E is E segment length.

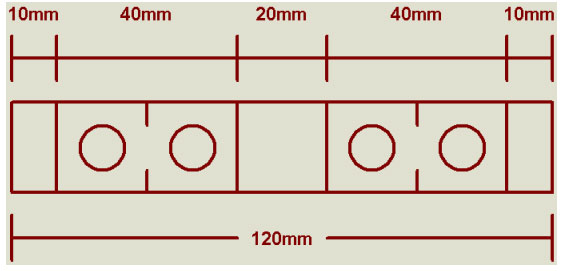

Several other filter bars containing beads are described below :

A filter is divided into 5 sections, and the middle two sections each have two lemon yellow beads

A complete filter bar is evenly distributed with 6 lemon yellow beads

In the production process, there will be blue beads are not placed or placed in place, and other serious defects affecting product quality. In order to avoid the beads composite filter rod forming machine online production process, due to various factors causing the composite filter stick beads in beads missing or wrong position into the phenomenon, thus forming a filter does not meet the quality requirements of the accident, but in this case it is difficult to identify the artificial. Therefore, this project uses the microwave detection principle, combined with the control system of the international advanced beads composite filter stick forming realize on-line microwave detection, found the quality defects of filter rod when tracking control to be removed, thus ensuring product quality.

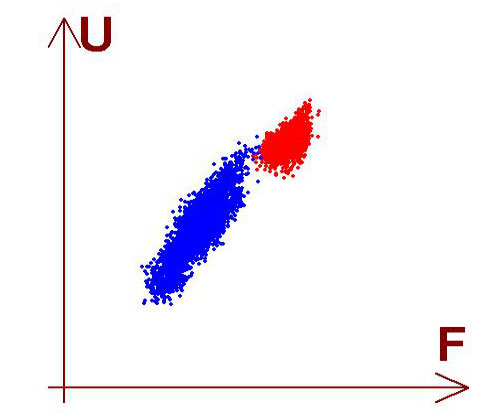

Part II. Principle of microwave detecting compound filter rod defect

Microwaves are part of the radio spectrum. It refers to an electromagnetic wave whose frequency is 300MHz (1 meters) to 300 GHz (1 mm wave length). Microwave technology is a technology based on the development of microwave characteristics. Its research contents include microwave generation, transmission, propagation, radiation, detection and application. Because of the high frequency microwave signal, change speed, is extremely sensitive to changes in reaction to different material resonant frequency and amplitude, and it is to produce any damage material itself will not be detected, so it can on-line, real-time, rapid and nondestructive detection of the characteristics of material properties. The microwave power used in this system is very small, only about 10mW, so it does not cause any pollution and damage to the work site and operators. Different materials will produce different microwave signals when passing through the microwave resonant cavity. In the composite filter bar, the A section material filter rod and B segment material (beads) filter stick should produce different microwave signals when passing through the microwave resonant cavity. Study on the development of my company personnel on the above signal composite filter stick in the microwave resonant cavity in the analysis, comparison, can clearly distinguish the microwave signal from the A segment and B segment material filter material filter, analysis results as shown below??/FONT>

In Fig. U, the amplitude of the microwave resonance curve is expressed; F represents the frequency of the microwave resonance curve. The red dot represents the microwave signal produced by the material filter bar of the A segment; the blue dot represents the microwave signal produced by the B segment filter rod ??/FONT> |